In the thin layers of the polymers oozing out of a machine that looks an expensive version of an ink jet printer lays the next frontier of electronics.

The research being done into new synthetic polymers in Simon Rondeau-Gagne’s University of Windsor lab is the first step in creating wearable electronics.

“Probably in the next decade every object is going to be connected through the Internet,” said Rondeau-Gagne, who accepted an assistant chemistry professor’s position at Windsor last July after completing his post-doctoral work at Stanford University.

“There’s a want for smart electronics. Stretchable electronics will be an important piece of the Internet of things.

“Once we have a material that is stretchable, robust enough to take repeated use and can self-repair, the potential is whatever industry’s designers can imagine.”

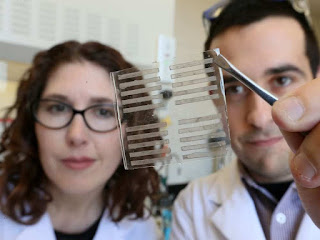

Rondeau-Gagne is combining his expertise in designing synthetic materials with Professor Tricia Carmichael, who has already built an international reputation for her work in the stretchable electronics field.

Carmichael, a researcher at IBM’s headquarters in Armonk, New York before returning to her hometown in 2005, said the two research teams offer complimentary skill sets.

“My team’s strength is we’re good at building things and working with different materials and integrating them into stretchable electronics that are stable and maintain their functionality,” Carmichael said.

“Simon is an expert in synthetizing different materials and designing them for different functions.

“Together we can do stuff that no one has ever done before.”

Beyond smart clothing that could monitor in real time the body’s condition, Rondeau-Gagne envisions such possibilities as stretchable electronics helping restore the electrical impulse connections in a damaged spinal cord or new materials in car doors that self-repair after being dented.

“I think one of the emerging uses will be in elder care,” Carmichael said.

“It allows for constant monitoring of pulse, blood pressure, sweat or where they are,” said Carmichael, who oversees a team of nine student researchers.

“However, there are still huge challenges to doing all these things.”

The first step is for Rondeau-Gagne to find the right material.

Rondeau-Gagne said what his research team of six students is doing is akin to building a foundation for stretchable electronics.

“It’s like sci-fi stuff,” said Rondeau-Gagne, a native of Chicoutimi-Saguenay.

“The material I’m working with looks like ink, but when it’s solid it looks like blue plastic.

“It makes a film, but it’s only 40 Nano-millimeters thick.”

Rondeau-Gagne already has been successful in creating a polymer containing transistors that could be ‘re-healed’ with heat.

He hopes to soon finish developing self-healing materials that don’t require an outside stimulus to allow Carmichael to use her expertise in stretchable electronics.

“I believe within a year we’ll reach that point,” Rondeau-Gagne said.

“Tricia has a real expertise in these electronic devices and stretchable materials. She’s had great results already using rubber materials.”

Indeed Carmichael’s team has already created a new type of rubber. It’s clear and impermeable to gases and was modification of the rubber used for the inner tubing in car tires.

“What we were able to do is develop a transparent version of this material,” Carmichael said. “That means we make displays to use in it.”

However, the ultimate goal is to find a synthetic compound that is more stretchable, can take repeated use, self-repairs and can handle the heat produced by the transistors and circuitry embedded in it.

“We already have materials that can be stretched 100 per cent,” Rondeau-Gagne said.

“However, even if it can stretch 10,000 per cent, if it can’t be stretched more than a couple times without the circuit breaking, we can’t use it. There’s going to be pressure and stretching all the time with wearable electronics.”

Carmichael said the field of stretchable electronics is developing rapidly with the growing investment from major corporations and foundations.

“Simple demos (of stretchable electronics) are real,” Carmichael said.

“There’s a huge community who make wearable electronics by sewing things into their clothes. There’s already a cottage industry.

“I visited a wearable electronics company in Toronto making real products – sweat sensors for clothing. It’s coming.”

No comments:

Post a Comment